Home > Conveyor Belt Guide With Video

From the farming community and need a replacement Baler Belt? we can help.

Our belts are manufactured from high quality material and suit a wide range of baler machines such as Claas, Vicon, Massey Fergusson and Welga.

We can also offer, on special order, belts for John Deere Baler machines as well as New Holland machines such as the 640 and 650 which can be supplied with truly endless belts.

A Techbelt best seller we have a wide range to suit ovens and curing units. All our belts are custom, in-house designed and are produced here by our engineering team; this means you can have the exact size you need.

Our main type of material used for these styles of dryer belts is a PTFE coated open mesh, depending on the type of dryer they are being fitted to, we can either specify standard brown or anti-static black versions. Our PTFE dryer belts will operate at 260°C and will work with UV, IR and hot air dryer methods.

PTFE coated conveyor belts are the belt of choice for machine manufacturers of fusing, laminating or powder coating lines.

The materials that are laminated are covered with a heat activated adhesive therefore the PTFE belt is an excellent choice due to its non-stick properties.

Also due to the high and low temperatures experienced immediately after each other within the process, the belts are well suited to handle this quick change in temperature.

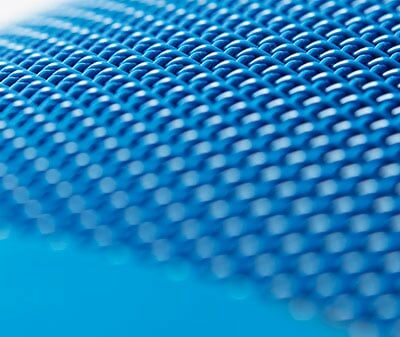

Polyester Monofilament process conveyor belting is available in a wide variety of yarn thicknesses and apertures. Polyester mesh is used as a carrier belt for drying within the printing and textile industry and also used as dewatering belts for fruit and vegetables in the food industry.

It has excellent chemical, thermal and high permeability for ease of cleaning. It has a working temperature: of +150°C to -75°C in dry conditions. 70°C+ in wet conditions. The nature of polyester belting is such that it offers a very durable long lasting media for extended life. Strong polyester fibres provide excellent stability.

Used in applications such as the drying of printed products for example; point of display stands, T-shirts, glass and mass produced paper prints.

PTFE open mesh belting is ideally suited for conveying products within highly efficient air distribution systems allowing optimised moisture removal to take place.

The PTFE open mesh conveyor belting is lightweight and has energy efficiency for economical operation, it is easy to handle and less expensive than wire alternatives that can be difficult to replace. The material property allows resistance to temperature.

Companies manufacturing packets of biscuits or toilet rolls would normally use these belts in order to seal the ends of the packets.

PTFE Sealer belts are ideally suited where thermal transfer through the surface of the belt is required in order to seal plastic materials.

The premium grade PTFE used to manufacture the belts has a non-stick, high temperature resistant surface that prevents any molten plastics from building up on the belts surface.

Ideally suited where thermal transfer through the surface of the belt is required in order to seal plastic bags.

High volume bag manufacturing systems often use these types of belts running as a pair creating a clamping effect on the bag.

It has a non-stick PTFE Surface, with a temperature resistant up to 260°C. It is very lightweight and energy efficiency for economical operation.

Polyurethane and PVC conveyor belting is used in almost all types of environments where anything from delicate food products and thin paper to heavy boxes and packaging require conveying from one area to another.

Conveyor Belts and Drive Belts play a major role in the manufacture and distribution of products in industries such as food, tobacco and logistics to name but a few.

Your individual requirements will determine the spec of belt design that you will need.

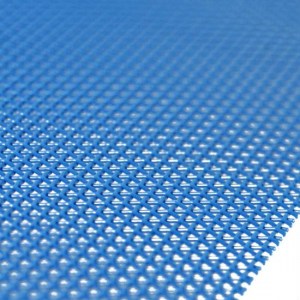

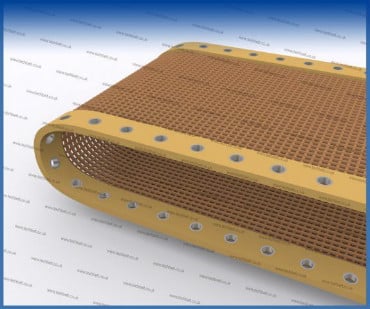

Modular belts are becoming more commonplace in a number of environments due to its durability and multi-functional properties.

Modular belting can be used to convey a multitude of products including bakery goods, wood, glass, raw materials, seafood, poultry and produce; because of its temperature range it can also be used for cooling and drainage.

Belt compounds are also available to enhance a wide range of belt properties that include diffusing static electricity build up, preventing freezing, increasing heat resistance, and increasing or reducing friction.

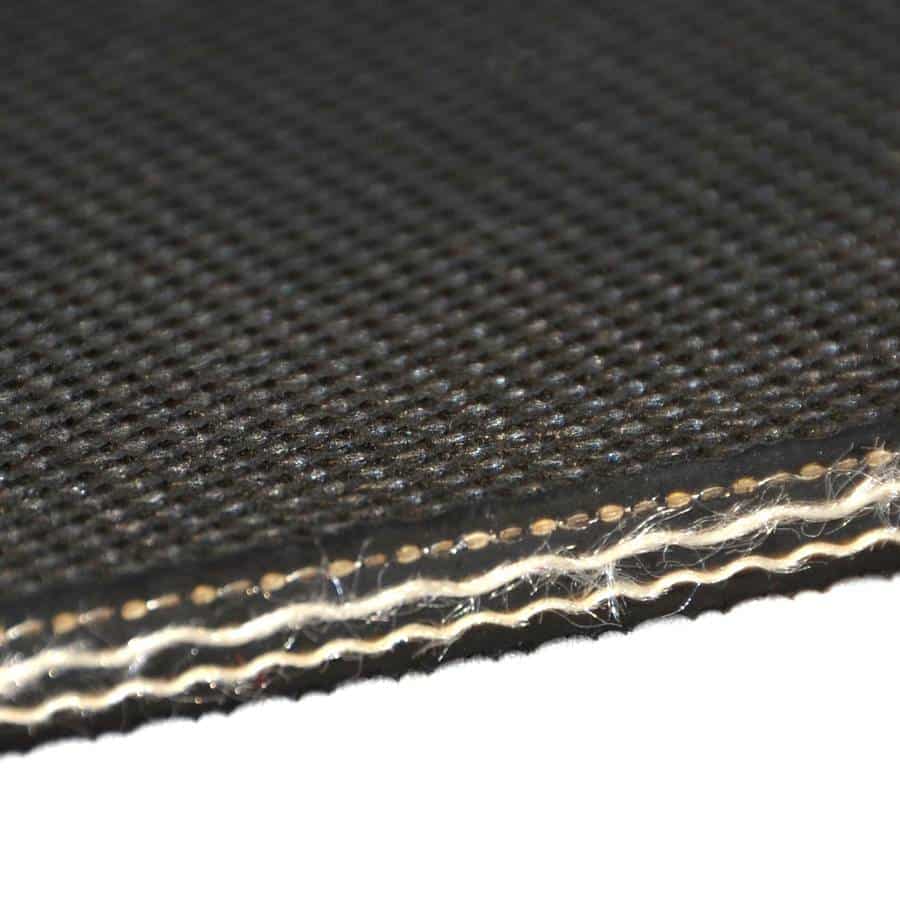

Tech-Grip roller coverings can be used on any conveyor that requires a friction surface to benefit the application.

It can be used to create extra drive on conveyor belts or simple as a friction surface to aid the flow of a product or material passing over.

Its material properties allow wide operating temperature ranges with superior mechanical grip. The micro cellular PVC sponge is ideal for uneven fabrics like brocade fabrics due to its softer nature avoiding damage to delicate fabrics.

It has a non-stick PTFE Surface, with a temperature resistant up to 260°C. It is very lightweight and energy efficiency for economical operation.

High temperature food grade belts can be used in a wide range of applications and are typically suited to dough pressing applications like Tortillas and oven conveying of Naan and Pita bread.

Also depending on the grade of belt it can be used for meat such as chicken breast, burgers and meatballs.

Our food grade belts have specially developed coatings that work hard to prevent fat ingression and wicking. They are available in a range of sizes and colours to suit your needs.

Polyester Dewatering belts are used as a carrier and transport belt in the food processing industry.

Typically they can be found in companies that process and wash vegetables and salads. These belts are offered in two colours which typically have a square aperture which allows for fast and efficient water drainage.

The material allows excellent chemical, thermal and high permeability for ease of cleaning.

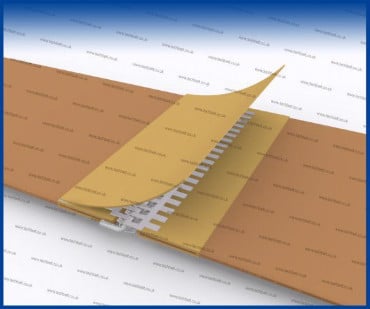

There are three mesh belt edgings. Firstly, PTFE Film Edging, which encapsulates the edge to help stop fraying and offer protection.

The benefit of using film is that it is soft in nature and will stretch with the belt when under tension.

Secondly we have, PTFE Glass Cloth, which can be used as a sturdier option to film and a good option if a tracking arm is used to detect the edge of the belt when coming into contact with it.

Thirdly we have, PTFE Coated Kevlar which is the most durable of the edging types and is a good option when the edge of the belt will be in contact with tracking aids. It is also a good option when considering using tracking studs of cord on the belt.

We have a range of Belt joints alligator, butt, castellated, clipper, cover, finger, overlap, scarfed, and spade.

These are available in various sizes with different capabilities for your needs.

These tracking aids usually are fixed to one edge on the conveyor belt with the head of the dot running on the inside of the belts circumference.

We have tracking aids and cords and we can help you decide which is best for you.

These include film edging, teflon edging, teflon glass edging, tracking eyelets, tracking cord and tracking studs.