Home > Architectural Membrane Welder

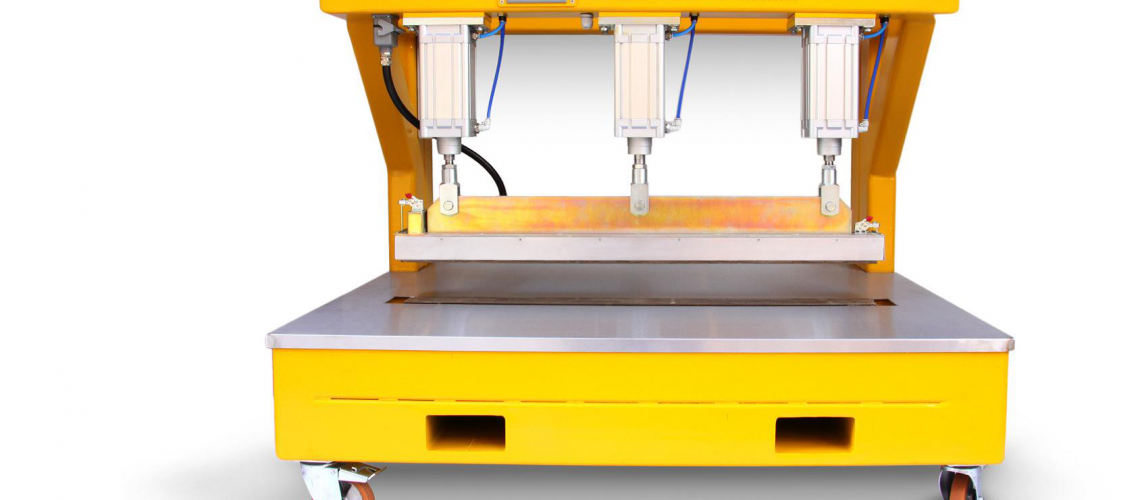

Techbelt developed the PTFE Architectural Membrane Welder to provide a user-friendly solution for welding the seams of PTFE and silicone-coated materials used in architectural tensile structures.

Architects increasingly incorporate tensile shades and roofing membranes into some of the world’s most impressive designs. Therefore, ensuring the quality and durability of these materials is essential.

Given their prominence in modern architecture, the quality and fabrication techniques of these materials are paramount. Thus, using high-quality materials and advanced equipment ensures that manufacturing is carried out with maximum effectiveness.

Moreover, the Architectural Membrane Welder’s design originated from a customer’s need for easy-to-use, reliable, and ergonomically friendly equipment. Through discussions and understanding the customer’s processes and fabrication techniques, we developed the welder with a temperature range up to 500°C, allowing the vulcanizing of both silicone and the much higher temperature PTFE-coated materials.

In conclusion, Techbelt’s Architectural Membrane Welder meets the rigorous demands of modern architectural projects, ensuring high-quality results for tensile shades and roofing membranes.

This equipment and all machines we manufacture have protected Intellectual Property rights and Copyrights owned by Technical Engineering Services Ltd and cannot be copied in anyway. By purchasing this equipment you agree not to make any copies or supply information to any third parties that will allow them to make such copies.