Home > PTFE Coated Fabrics

PTFE-coated fabrics are high-performance materials used in a wide range of applications. These materials offer non-stick surfaces with excellent resistance to extreme temperatures.

Applications for PTFE-Coated Fabrics

PTFE-coated fabrics are used in a variety of industries and applications:

Features & Benefits

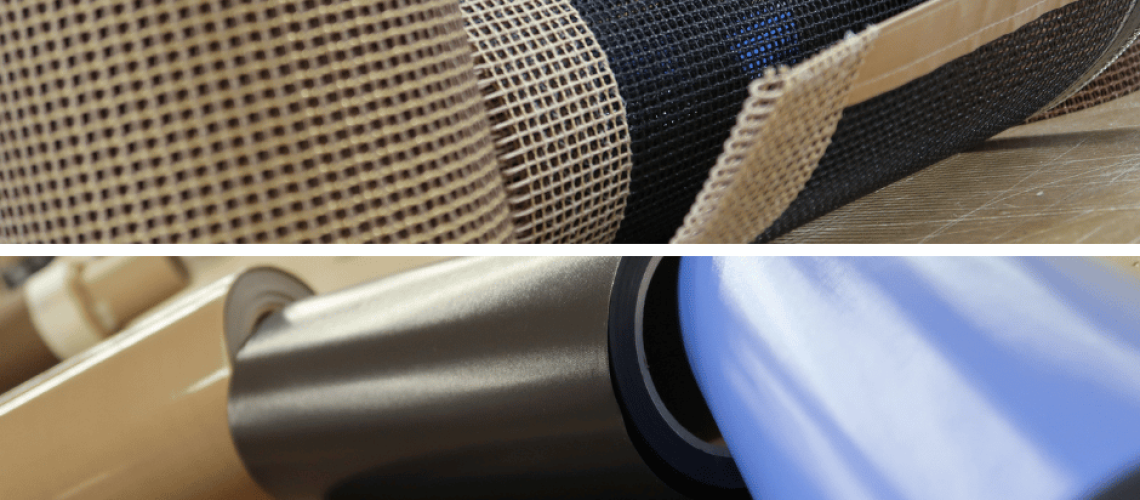

The properties of PTFE-coated materials make them an excellent choice for use in cooling chambers and freezing temperatures, as well as high thermal environments. The PTFE is coated onto either a fiberglass or Kevlar substrate. Both substrates offer high levels of temperature resistance, with Kevlar being beneficial in applications requiring additional strength or where steam is present.

Material Properties

Additional Information

Techbelt’s PTFE-coated fabrics are available as slit rolls in adhesive-backed form, sheet rolls in non-adhesive form, or converted into specialized conveyor belting. Material widths can vary but are available up to 197 inches wide, depending on the grade and requirement.