Who Invented Conveyor Belts?

Who invented conveyor belts? People often credit Thomas Robins with inventing the modern conveyor belt. In 1892, he

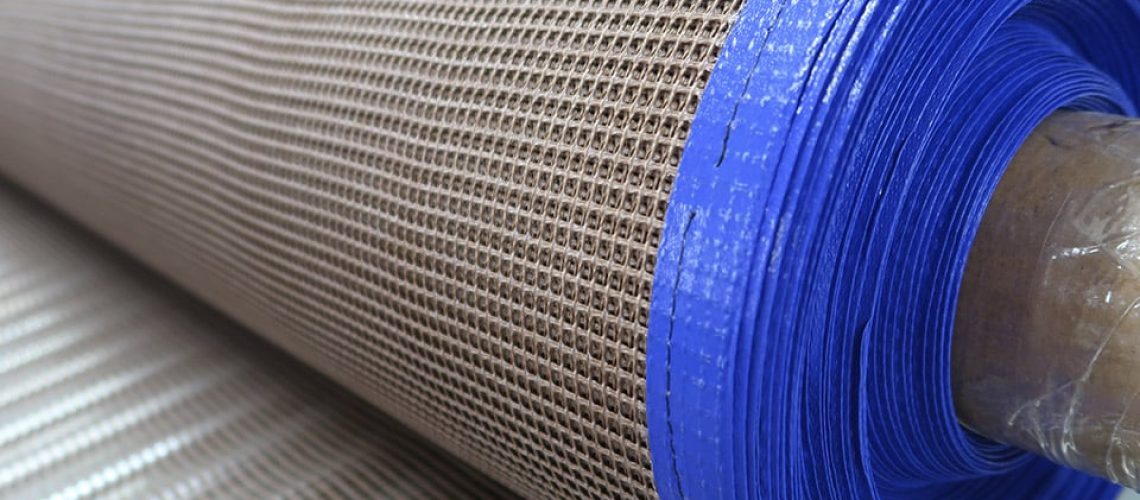

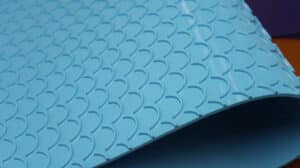

Screen Printing Mesh Belt USA are essential for curing screen-printed products. These belts come in various styles to suit different applications, from small occasional-use ovens to large industrial dryers designed for high-volume output.

There are three main types of conveyorized dryers:

Forced air dryers are used when the ink doesn’t need high-intensity heat. They can run with either PTFE screen printing belts or polyester monofilament mesh belts.

Infrared dryers cure inks similar to those used in forced air dryers, including discharge, water-based, plastisol, and two-pack inks. PTFE mesh belts are ideal for these dryers, especially with reinforced edges.

UV dryers cure ultraviolet surface coatings applied to various products like glass, promotional items, and telecommunication products. PTFE-coated mesh belts are preferred due to their high-temperature rating.

Techbelt can meet any special requirements for screen printing belts, including custom sizes and special widths. We assist with dispatch, customs, and shipping. With over 20 years of experience, we ship to over 30 destinations worldwide.

For more information or to discuss your Screen Printing Mesh Belt USA needs, contact our Technical Sales team:

Who invented conveyor belts? People often credit Thomas Robins with inventing the modern conveyor belt. In 1892, he

Conveyor belts are used in a wide variety of industries and applications to efficiently transport materials. Here are

Wondering how to design a conveyor belt that perfectly suits your specific needs? At Techbelt USA, we make