What Is A Timing Belt?

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving parts of many machines. The reliability and

Home > BLOG

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving parts of many machines. The reliability and

Wow, what a journey it’s been! We’ve always believed in the power of LinkedIn to help us connect, share, and grow. This milestone wouldn’t mean

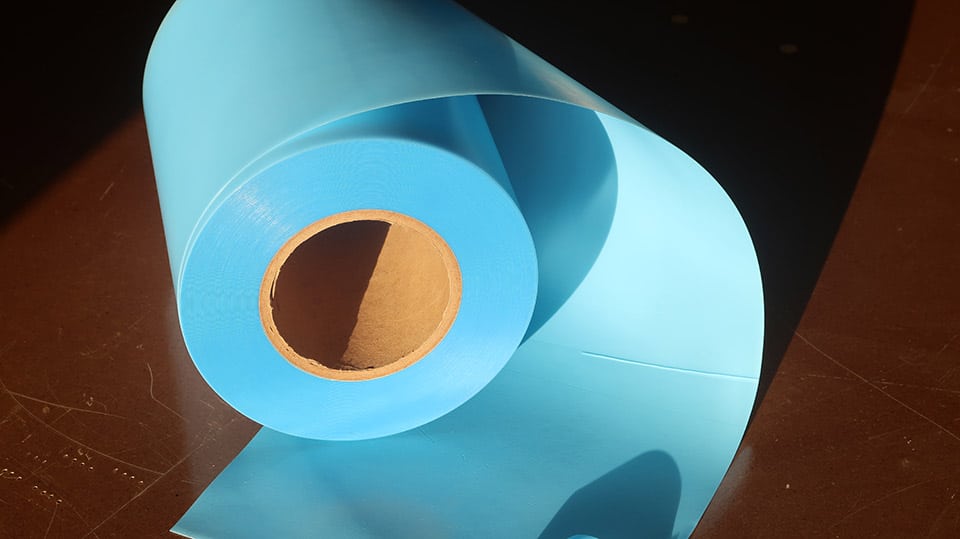

UHMW tape Ever struggled with things wearing out too quickly or noisy machinery that’s just a constant headache? We get it- whether it’s on a

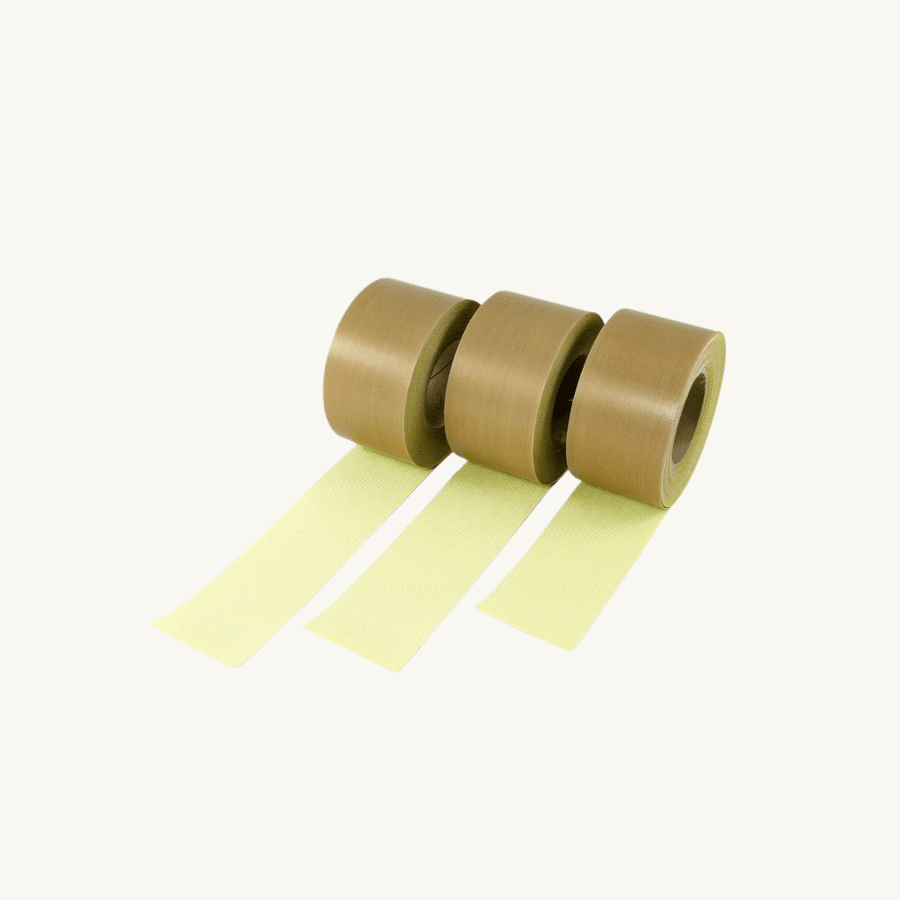

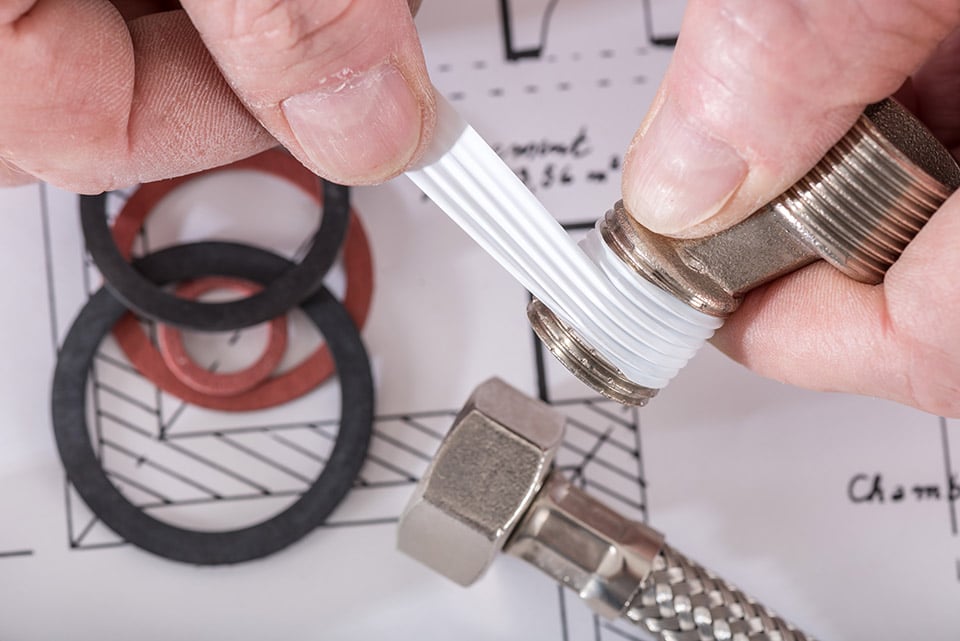

The Accidental Discovery of PTFE When was PTFE Discovered? Ptfe was discovered In 1938 when Dr. Roy Plunkett, a chemist working for DuPont, was experimenting

Ever wonder what PTFE Stands For? Have you ever flipped a perfect pancake without a single tear? Or maybe you’ve marveled at the smooth glide

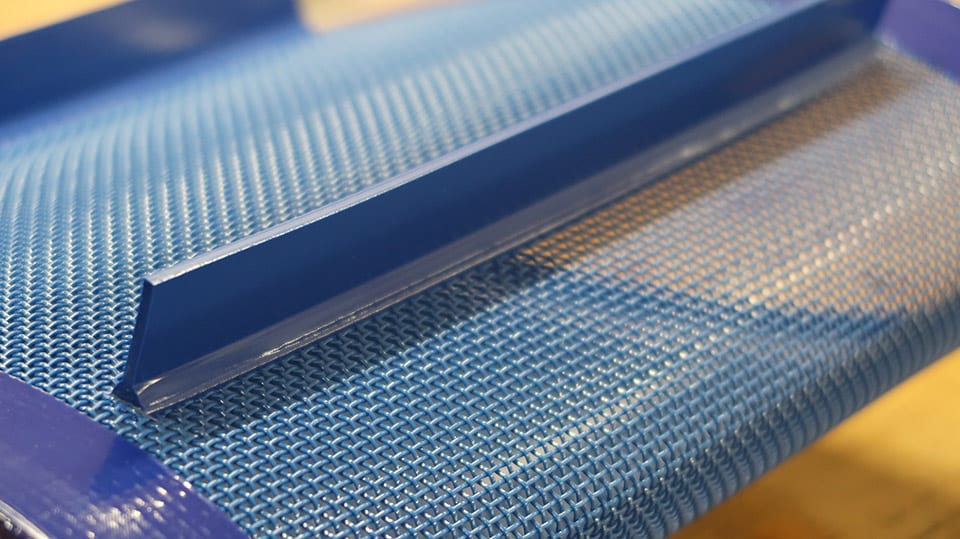

We do love a Polyester Dewatering belt at Techbelt! 😍🔵 Our Techpol 2000 Dewatering belt is a high performance belt that is equipped with T30

Ever heard the saying ‘a stitch in time saves nine’? …. Well, a patch in time can save you buying a whole new belt! 🧵💪

We’re thrilled to welcome Jo , our new Business Development Manager, to our ever-growing team! With years in the conveyor belt industry, Jo brings a

We’re thrilled to introduce Danny to our expanding sales team! As a sales administrator with 13 years of experience, Danny brings a strong customer focused