Home > Hygiene Roll Packaging Belts

Hygiene roll packaging machines are designed to pack many types of rolls but mainly toilet tissue packs. We supply hygiene roll packaging belts for these machines for any make/model.

As the rolls are stacked into packs of two or more with plastic film wrapped around them.

Once fully wrapped the ends are finished in the style of an envelope once sealed.

The enveloped plastic ends need to then be heat sealed as the pack travels along the production line through the hygiene roll packaging belts.

In order to achieve this, there is a bank of heaters on each side of the pack which provides the heat source to melt the enveloped ends down.

If the plastic came in to direct contact it would stick and melt the pack preventing it from sealing properly and prevent the line from working.

In order to overcome this potential problem, two endless PTFE sealer belts are used in pairs to create a heat resistant barrier and non-stick surface.

He belts run on their side and usually have some king of tracking aid to keep the belt in position when running.

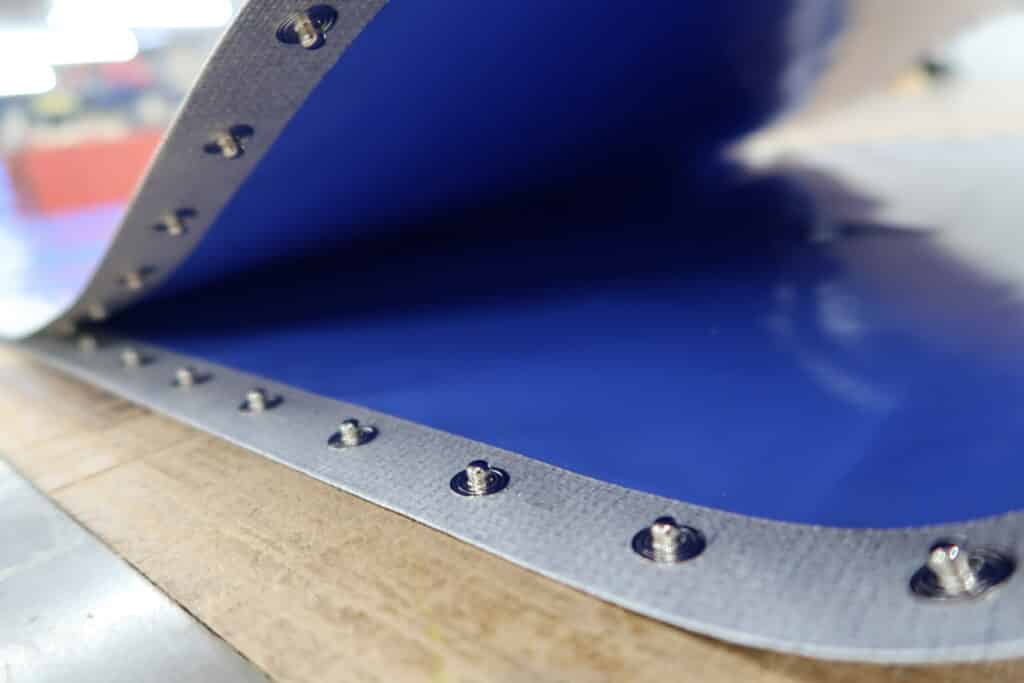

Some special belts made by an OEM utilise a spring that is fitted to the edges of the belts and some older machines use fitted studs that look similar.

At Techbelt we opt to use a special, anti-tear, heat resistant film that provides both tracking benefits and extra edge protection helping to provide extra belt life.

Find Out More