Home > PTFE Heat Press Sheets

PTFE Heat Press Sheets: Unleashing Non-Stick Heat Transfer Power

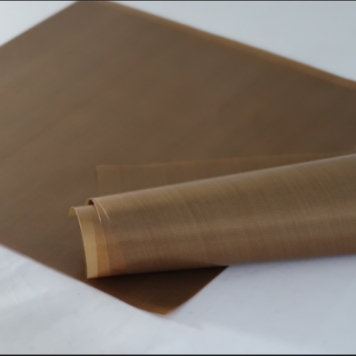

PTFE heat press sheets, also commonly known as Teflon sheets, play a vital role in the realm of heat transfer printing and vinyl applications. Crafted from PTFE (polytetrafluoroethylene), a synthetic fluoropolymer, these sheets boast exceptional non-stick and heat-resistant qualities. This comprehensive guide will plunge into the world of heat press sheets, providing insights into their nature, functionality, unique advantages, and versatile applications in the custom printing industry.

What Are PTFE Heat Press Sheets?

PTFE, or polytetrafluoroethylene, stands as a high-performance, non-stick material renowned for its exceptional resistance to heat and chemicals. Heat press sheets take the form of thin, flexible sheets or rolls fashioned from this remarkable substance. They serve as protective barriers and non-stick surfaces throughout heat transfer processes, ensuring the preservation of heat-sensitive materials and heat presses.

How Heat Press Sheets Operate

The utilization of PTFE heat press sheets in the heat transfer process encompasses several key steps:

The Benefits of Heat Press Sheets

PTFE heat press sheets offer several distinct advantages:

Diverse Applications of Heat Press Sheets

PTFE heat press sheets are applied in various industries, including:

eat press sheets emerge as the unsung champions of the heat transfer domain, ensuring the preservation of heat-sensitive materials and the upkeep of a pristine heat press machine while delivering vivid and enduring designs. Their non-stick attributes, resistance to high temperatures, and durability render them an indispensable tool for anyone involved in custom printing, from small-scale artisans to professional apparel decorators. Seize the potential of PTFE heat press sheets to unleash your creativity and bring your unique designs to life.

Our business is built on service. We place a high value on being able to support our customers in all areas such as the speed we provide our quotations and the time we take to deliver our goods to the customer.

Techbelt has family business values with global reach. We supply to over 50 countries worldwide and strive to continue to offer our specialist products whatever your geographic location.

With a Technical Sales Team that has over 80 years of experience between us, we welcome any challenging request and thrive on providing technical solutions across our range of products

We are passionate about our customers and are proud to have served over 3000 customers. We aim to expand on this to build more long lasting relationships.

We aim to dispatch all customer orders for slit tapes within 1 – 2 working days. Our full time slitting department is on hand to ensure all cut rolls go straight into production on the day they are ordered.

Without you, we don’t have a business. Every member of the Techbelt team is passionate about serving our customers. Extra care and passion is taken right through from sales to our manufacturing team.