Home > Plastic Film Shrink Tunnel Belts

Packaging shrink wrap tunnels tend to use PTFE mesh plastic film shrink tunnel belts, silicone coated glass cloth or metal type belts.

Techbelt manufactures both the PTFE and silicone belt in house.

Products that need to be shrunk wrapped in either a PVC or polyolefin shrink film are first sealed in oversize pouches in a heat or l sealer.

They passed on to either of a silicone or a PTFE film shrink tunnel belt that convey the pouch through a small over that provides the heat to shrink wrap the film around the product.

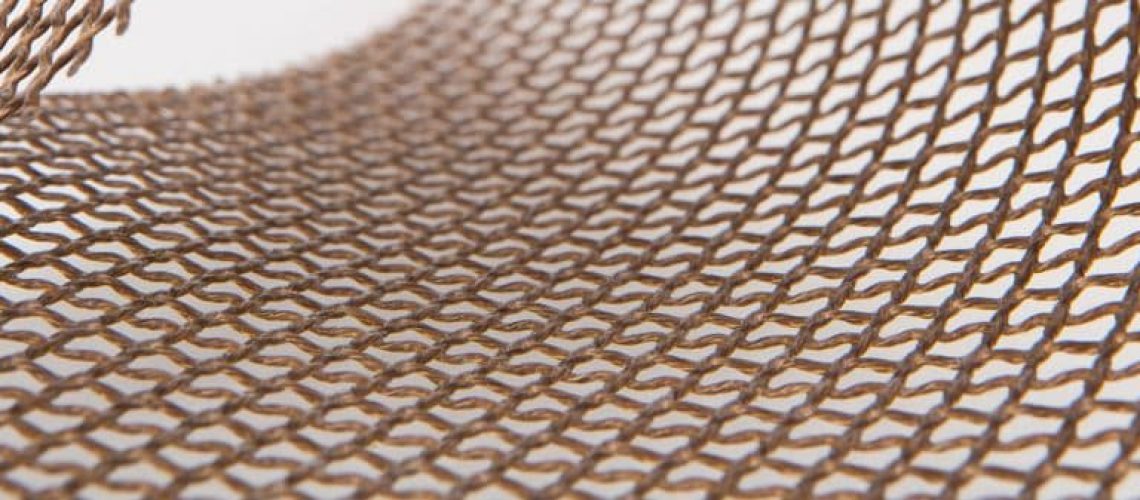

If an oven relies on a lot of circular air flow to shrink the films then a PTFE mesh belt would be a more suitable option as the mesh allows airflow to travel through it.

Silicone glass cloth belts are solid, closed weave types and hold surface heat very well.

This is sometimes beneficial as the surface can still hold heat in its surface on the return leg of the belt aiding the film to shrink when placed on the plastic film shrink tunnel belts surface as it enters the oven.

Silicone belts can be supplied as open length pieces and fitted by the end user on the machine with instructions provided by Techbelt. We also supply special RTV adhesive that will bond the belt together once in position.

The PTFE plastic film shrink tunnel belt more than often are supplied with end fitted with a mechanical fastener allowing easy fitting and replacement when required.

The mesh belts also come with an edge reinforcement as standard with a number of options available.