Home > Cross Lapper Belt

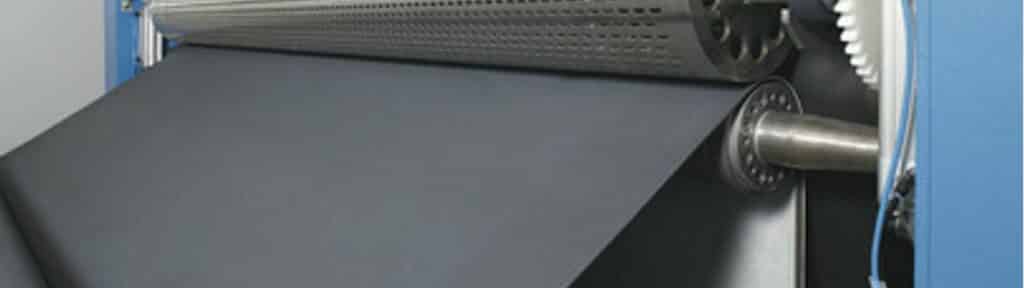

A cross lapper belt is used on a cross lapper machine within the textile processing industry.

Cross lapper machines are designed to stack multiple layers of non woven synthetic fibres on top of each other.

This is often done by adding the next layer at 90 degrees to the next. The reason for this is to apply a different direction to the fibres on each layer.

The more layers that are applied the longer it takes for the fibres that have been cross lapped take to exit the machine.

The requirement for higher quality cross lapper belts is increasing as the manufacturing process and efficiency improves. Increased demand is driven by the speed and the accuracy in which the synthetic fibres are laid together.

There are many different constructions for of a lapper belt but in its simplest form there are two. These can be broken down as either a smooth surface top or a grip top.

It is desirable to have a belt that is as light as possible. This assists with the speed a machine can run. It is also important that the conveyor belt has lateral stability too and cannot easily buckle across its width as it runs.

The installation of a cross lapper belt can be fairly difficult. This is because the belts can be as wide as 2400mm and are often situated high above ground level.

Because of the size of the belts they are generally heavy and difficult to lift into position. Working at height with a belt joining press also can make this a complicated installation.

Find Out More