Home > PVC Belting

In the world of material handling and industrial conveyor systems, PVC emerges as a versatile and indispensable workhorse. This blog post embarks on a journey to explore its characteristics, applications, and impact on various sectors.

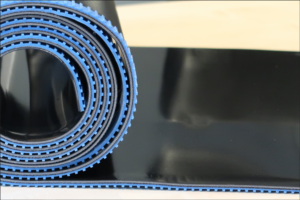

PVC belting, often abbreviated as PVC belts, is a conveyor belt crafted from polyvinyl chloride, a synthetic plastic polymer. Manufacturers produce it through the calendering or extrusion process, resulting in a robust, flat belt with a smooth, non-porous surface.

Food Processing and Handling

PVC belting plays a prominent role in the food industry, from bakeries to meat processing plants. Its properties make it an ideal choice for conveying food products. The smooth, non-porous surface is easy to clean and prevents the absorption of liquids and food particles, ensuring hygiene and safety.

Agriculture

In the agricultural sector, PVC belts are used for various purposes, including grain transportation, sorting, and packaging. Their resistance to moisture and abrasion proves valuable in the farming environment.

Manufacturing

Manufacturing facilities rely on these belts to automate their production lines, transporting a wide array of items, from electronic components to automotive parts with precision and reliability.

Recycling

In recycling plants, these belts are instrumental in sorting, processing, and transporting recyclable materials such as plastics, paper, and metals, thanks to their durability and resistance to moisture.

Airports and Distribution Centers

PVC belts play a pivotal role in airports and distribution centers by efficiently moving baggage and packages. The smooth surface reduces friction, ensuring timely and accurate handling.

Beyond these core sectors, PVC belting finds applications in logistics, and packaging making it an essential component of the modern supply chain.

In conclusion, the versatility and adaptability of PVC belts are instrumental in various industries, facilitating the seamless and efficient movement of products and materials. Their non-porous surface, durability, and resistance to moisture and abrasion establish them as valuable assets for a multitude of applications. As industries continue to evolve, PVC belts are to remain pivotal elements of their success, ensuring the smooth and secure movement of goods from production to the consumer’s hands.

Our business is built on service. We place a high value on being able to support our customers in all areas such as the speed we provide our quotations and the time we take to deliver our goods to the customer.

Techbelt has family business values with global reach. We supply to over 50 countries worldwide and strive to continue to offer our specialist products whatever your geographic location.

With a Technical Sales Team that has over 80 years of experience between us, we welcome any challenging request and thrive on providing technical solutions across our range of products

We are passionate about our customers and are proud to have served over 3000 customers. We aim to expand on this to build more long lasting relationships.

We aim to dispatch all customer orders for slit tapes within 1 – 2 working days. Our full time slitting department is on hand to ensure all cut rolls go straight into production on the day they are ordered.

Without you, we don’t have a business. Every member of the Techbelt team is passionate about serving our customers. Extra care and passion is taken right through from sales to our manufacturing team.