What Is A Timing Belt?

Timing belts are crucial components in conveyor belt systems and other machinery. They ensure precise synchronisation between the

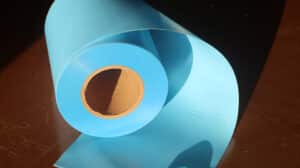

In the fast-paced world of manufacturing, where efficiency and reliability are non-negotiable, Techbelt’s tear-resistant PTFE belting stands out as a game-changer, especially within the hygiene industry. One of its standout applications is in the packaging of toilet rolls, showcasing remarkable material properties that have the industry buzzing with excitement. Let’s delve into the exceptional features that define this PTFE belting.

Ready to elevate your manufacturing operations with Techbelt’s tear-resistant PTFE belting? Our dedicated technical sales team is here to provide all the information you need and help you explore the immense potential of this cutting-edge technology. Feel free to reach out via email at sales@techbelt.com or by phone at +44 (0) 1422 366386. Discover more about our offerings by visiting www.techbelt.com. Let Techbelt guide you into the future of manufacturing technology!

Timing belts are crucial components in conveyor belt systems and other machinery. They ensure precise synchronisation between the

Wow, what a journey it’s been! We’ve always believed in the power of LinkedIn to help us connect,

UHMW tape Ever struggled with things wearing out too quickly or noisy machinery that’s just a constant headache?