What Is A Timing Belt?

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving

This video shows how to bond two layers of PTFE coated Kevlar / Aramid coated glass cloth together using our custom build bonding machine.

This video shows how to bond two layers of PTFE coated Kevlar / Aramid coated glass cloth together.

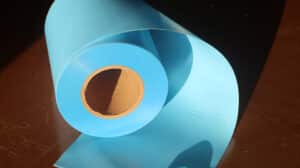

We have used a transparent PFA welding film in between the two-layer, which is the bonding film. On top of the joint, we have used a blue cast film. This film is used to create a smoother step where the lip of the material is. This will reduce the potential for lifting or catching in this area.

We have used one of our HWI-155 irons which are designed and built by Techbelt. This iron is set to 380C however we can change the settings for you should you need to a higher temperature.

We typically hold the iron in one place before moving on for around 60 seconds. This can be tested before welding on an off-cut of material to check the time and temperature is correct.

The red weight is used after the heat of the iron is removed to allow cooling under slight pressure. This helps to keep the joint as flat as possible.

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving

Wow, what a journey it’s been! We’ve always believed in the power of LinkedIn to help us connect,

UHMW tape Ever struggled with things wearing out too quickly or noisy machinery that’s just a constant headache?