What Is A Timing Belt?

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving

PFA Film

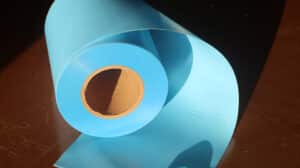

PFA film is a fluoropolymer film that is manufactured from perfluoroalkoxy (PFA) polymer resin.

What temperature will it continuously work at?

PFA film offers the highest continuous service temperature being 260°C (500°F) of any melt-processable fluoropolymer film.

How can it be processed?

We stock this film in a a transparent form. It can be laminated to a wide variety of materials as well as be heat sealed. In addition to this it can also be thermo-formed and heat welded.

What property benefits does it offer?

PFA film offers many of the performance benefits and properties of PTFE (polytetrafluoroethylene). Techbelt PFA film offers a combination of excellent dielectric properties across a wide frequency and temperature range. PFA also offers the highest level of stress crack and chemical resistance.

What can it be used for?

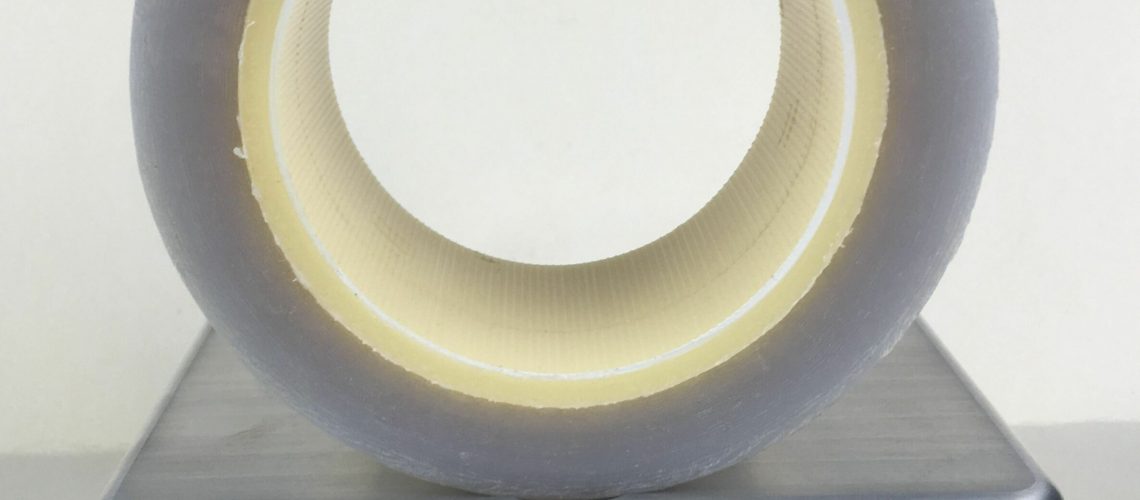

PFA can be used for a wide range of application however Techbelt uses this for the bonding of PTFE materials together. We manufacture and design machinery especially to do this.

How do you bond this to PTFE in your welding machinery?

The machine is essentially two metal plates that are heated up to around 380 °C. They apply pressure and heat for a given time which them allows the it to melt and bond. Once cooled the two surfaces are bonded together.

What thickness do you stock?

We generally stock our PFA film at 1200mm wide which can then be slit to widths to suit your requirement. The narrowest width we tend to cut to is 15mm wide.

What is the lead time for supplying ?

We generally slit this material the same day as it is ordered. Most of the time the material will dispatch that day on UPS.

How can I get in tough with Techbelt?

Please call us on +44 (0)1422 366386 or email sales@techbelt.com where one of our Technical sales advisers can help.

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving

Wow, what a journey it’s been! We’ve always believed in the power of LinkedIn to help us connect,

UHMW tape Ever struggled with things wearing out too quickly or noisy machinery that’s just a constant headache?