What Is A Timing Belt?

Timing belts are crucial components in conveyor belt systems and other machinery. They ensure precise synchronisation between the

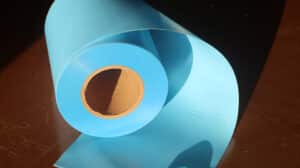

Techbelt designs Anti-Static Belting for industrial applications where static control, thermal stability, and consistent belt performance matter. As part of this approach, we manufacture these belts in-house in the UK, combining PTFE’s proven performance characteristics with anti-static properties. As a result, the belts suit fusing, laminating, and other high-temperature conveyor processes.

At a material level, Techbelt produces Anti-Static Belts using PTFE-coated glass fabrics with carbon loading to deliver reliable anti-static performance. Through this construction, the belt dissipates static charge while continuing to deliver PTFE’s core benefits, including excellent heat resistance, non-stick surface properties, and chemical inertness.

In addition, Techbelt reinforces belt edges with PTFE adhesive tape to improve durability and dimensional stability. This reinforcement reduces edge wear and shrinkage and, at the same time, provides a stable base for eyelets or fasteners where required.

In practical use, Techbelt Anti-Static Belting operates reliably in elevated temperature environments typical of fusing machines and industrial processing lines. Here, the combination of PTFE coating and glass reinforcement delivers stable performance under heat while maintaining smooth product transfer and resistance to contamination.

At the same time, carbon loading delivers anti-static functionality without reducing the temperature resistance expected from PTFE conveyor belting.

As a result of these performance characteristics, engineers specify Techbelt Anti-Static Belting for:

Fusing and laminating machines

Industrial conveyor systems that require static dissipation

Powder coating and finishing processes

Heat treatment and curing applications

In these environments, the belts perform particularly well where static build-up affects product handling, surface finish, or belt tracking.

From a manufacturing perspective, Techbelt produces Anti-Static Belting to order, allowing belts to match customer-specified widths, lengths, and fastening configurations. Where required, we integrate eyelets with spring systems to support belt tracking and drive engagement in line with machine design.

Throughout this process, Techbelt’s technical team works with customers during specification to ensure correct belt selection for each application.

Where applications require airflow or reduced contact area, Techbelt also supplies Anti-Static Mesh Belting manufactured from black PTFE-coated mesh fabric. In this case, reinforced edges and durable spiral joint fasteners provide a robust alternative anti-static solution for specific conveyor and processing requirements.

Finally, Techbelt supplies belting worldwide and supports customers with technical advice, bespoke manufacturing, and logistics. For quotations or application guidance, customers can contact the Techbelt sales team directly.

Timing belts are crucial components in conveyor belt systems and other machinery. They ensure precise synchronisation between the

Wow, what a journey it’s been! We’ve always believed in the power of LinkedIn to help us connect,

UHMW tape Ever struggled with things wearing out too quickly or noisy machinery that’s just a constant headache?